INDUSTRIAL APPLICATIONS

Carbon Tooling

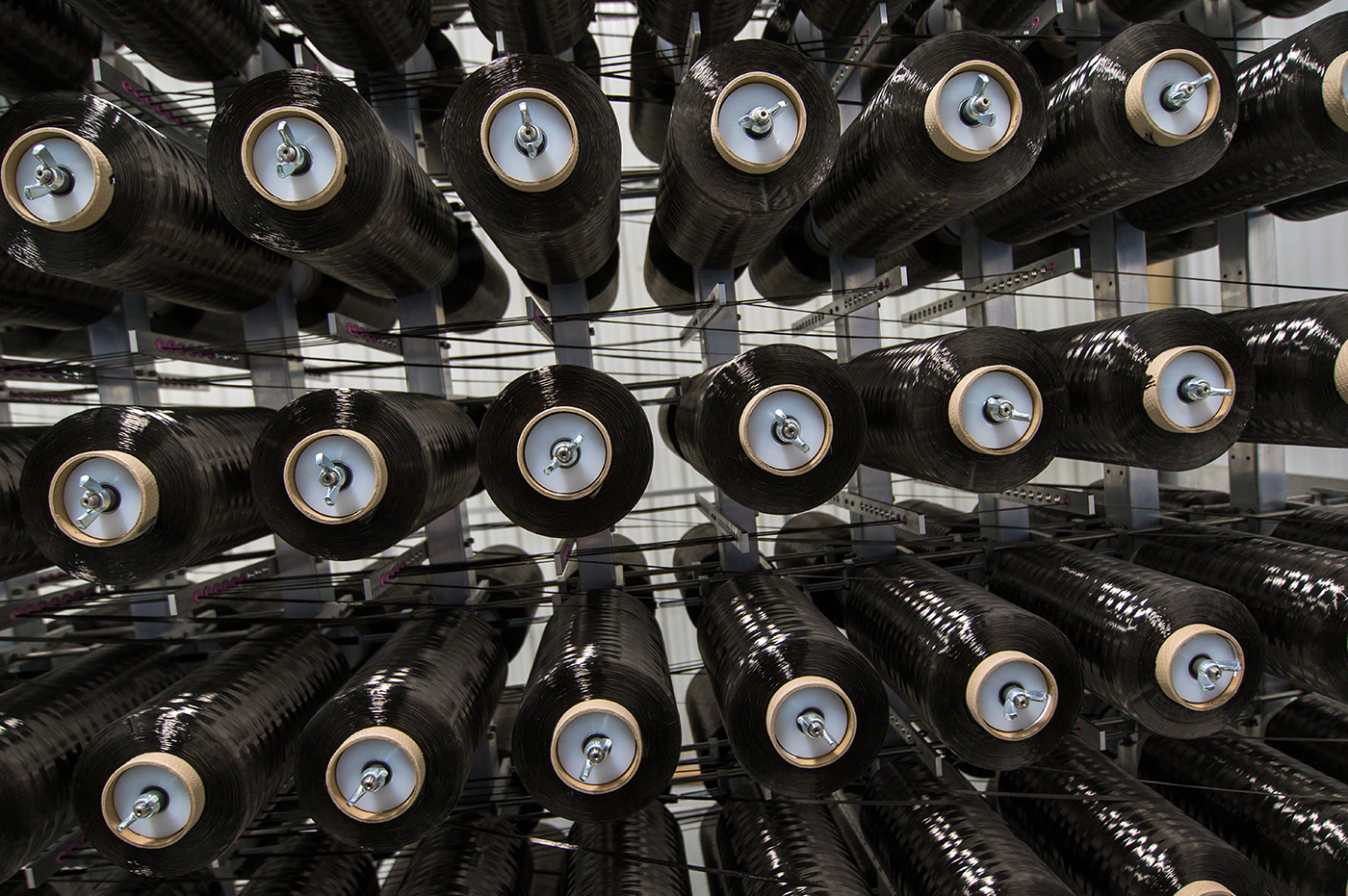

Another issue facing the tooling industry is variations in fibers used to produce carbon reinforcements. When different fibers are used, the sizing is not the same and they may not adhere as well to the resin system, which can affect the life of the mold.

To eliminate this problem, NRG uses the same fiber for all its productions. The type of fiber we use in our carbon reinforcements is included in the product number, so you always know what you’re getting.

NRG seeks to be your preferred partner by going above and beyond to ensure the quality and consistency of your tools.

Carbon Parts Production

The quality and consistency of NRG reinforcements make them excellent inputs for the production of high-performance parts.

Factors to consider when producing parts include consistent mechanical performance, weight, and lifespan. The part’s lifespan is a direct result of the first two factors.

Several factors go into producing high quality parts, including consistent inputs and a consistent production process. Because we put the same level of care into our parts as we do our tools, NRG can help by supplying you with top quality reinforcements that minimize weaving defects. Our customers don’t have to worry about introducing a new variable into their production process because we always use the same fiber input with the same sizing. That means our laminates are as consistent as possible and the fiber is always compatible with the resin system.

NRG seeks to be your preferred partner by going above and beyond to ensure the quality and consistency of your parts.